Bag Handling Conveyor

- Solutions By Product

- MHE Material Handling Equipment

- Conveyors

What is an Industrial Bag Handling Conveyor System?

Why Use Automated Bag Conveyors?

INDUSTRIAL BAG HANDLING CONVEYOR SYSTEMS

Our bag conveyor systems perform many actions supporting the bagging process including tipping, flipping, turning, straightening, and flattening. They can also check-weight, print, label, and transport filled bags. In short, everything needed from bag filling to palletizing. Additionally, we provide world-class conveyors for bag transfer, incline, closing, v-through, and reject. Lastly, we offer bag kickers and weighers.

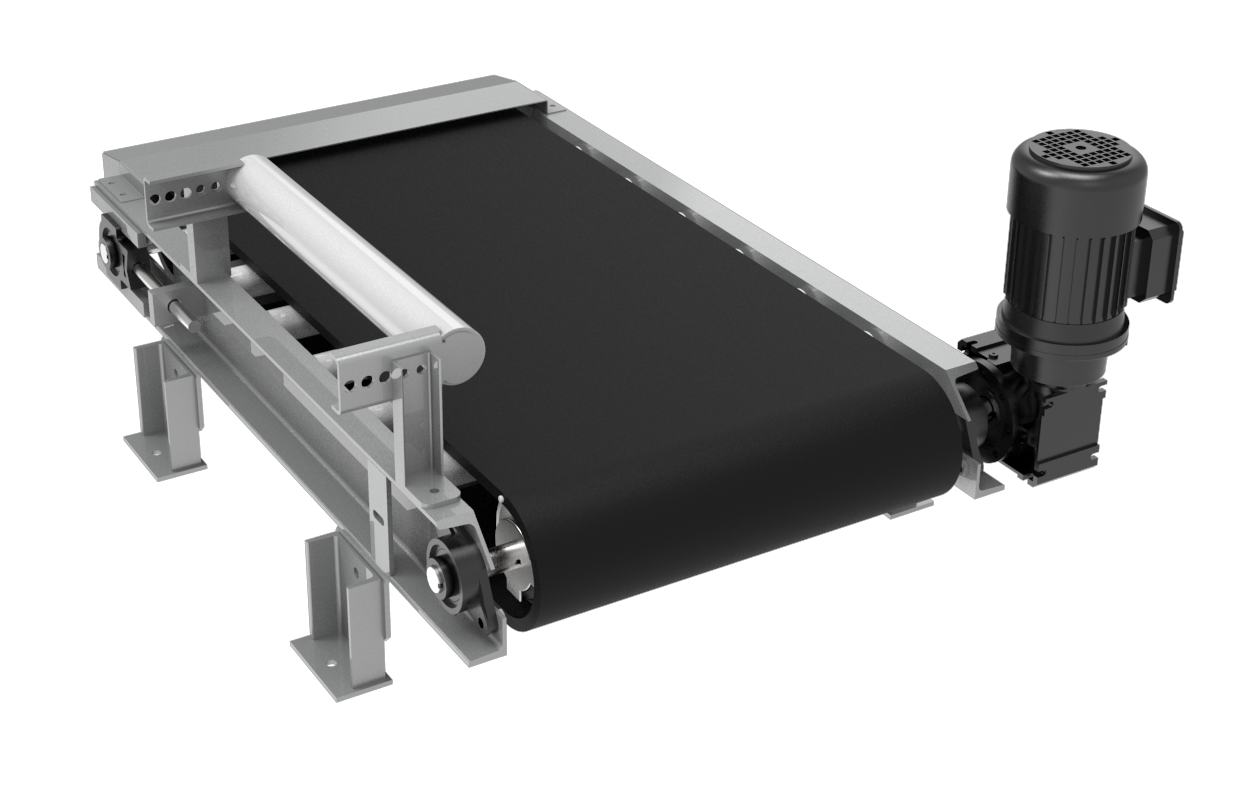

- Bag Transfer Conveyors

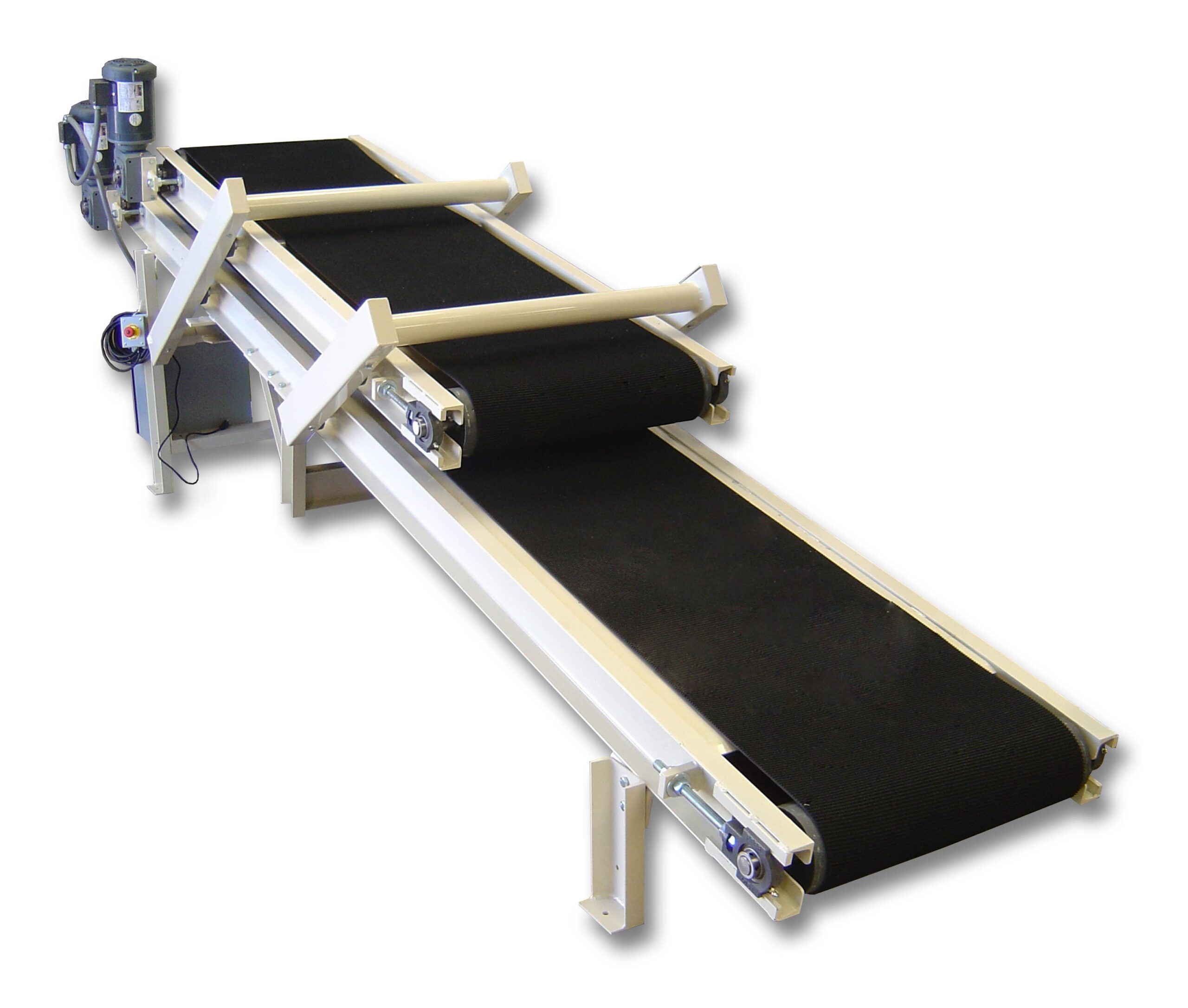

- Bag Incline & Transport Conveyor

- Incline Bag Flattener Conveyors

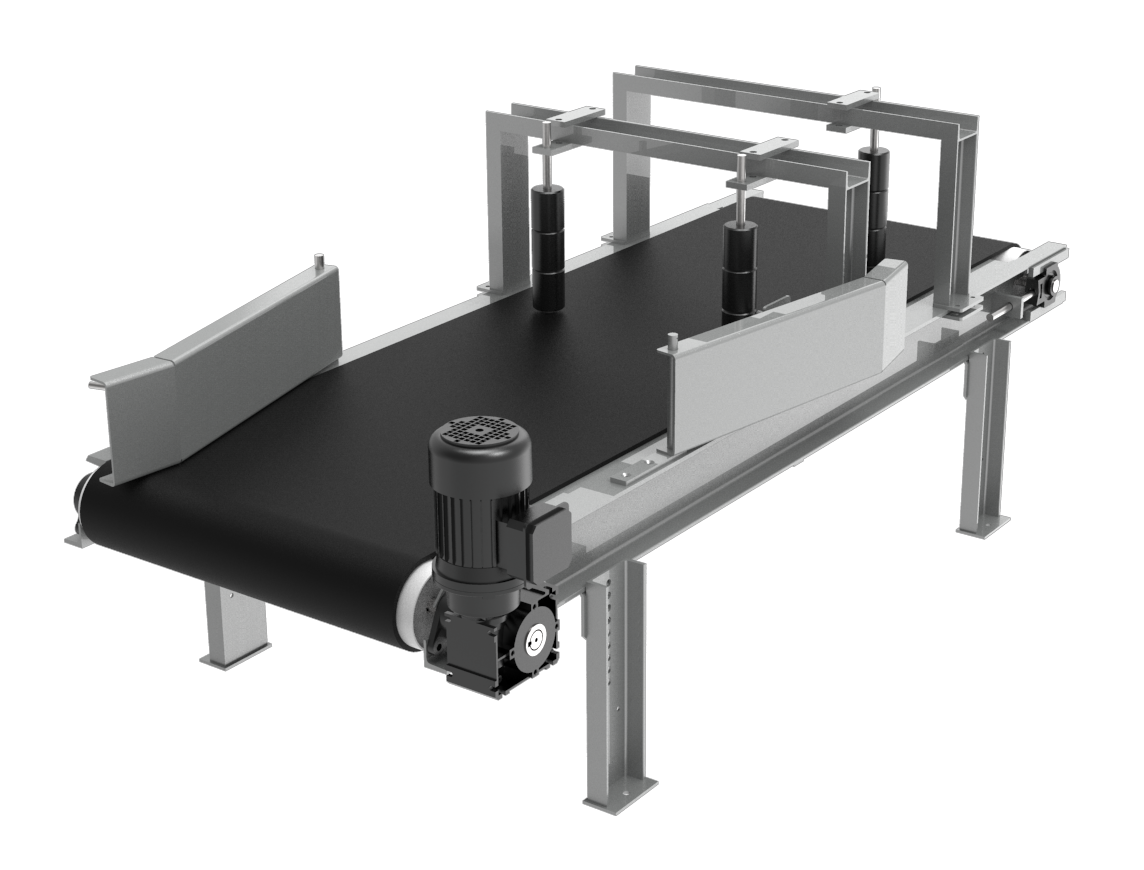

- Bag Turner Conveyors

- Bag Closing Conveyor

- Bag Turning & Knockdown Conveyor / Stackers

1) Bag Transfer Conveyors

Bag Transfer Conveyors are designed to turn bags 90 degrees transferring them from upstream to downstream conveyors. They work well in any situation where the conveying line and filled bags require an abrupt change in direction.

2) Bag Incline & Transport Conveyor

3) Incline Bag Flattener Conveyors

4) Bag Turner Conveyors

5) Bag Closing Conveyor

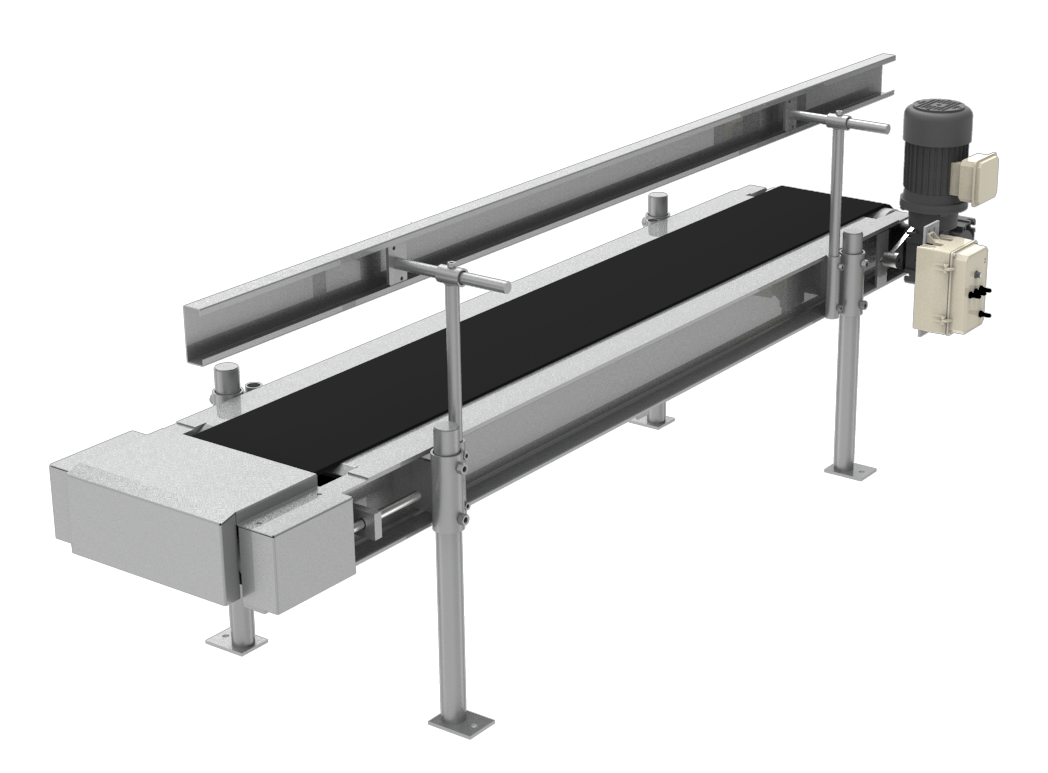

6) Bag Turning & Knockdown Conveyor / Stackers

DESCRIPTION OF KNOCKDOWN CONVEYOR

COMPONENTS

The system consists of a single belt 42”long x 24”wide. This belt is smooth top design to allow bag to easily slide over belt surface. The belt operates at 60 ft. per minute speed. If this speed is not adequate for the speed of your operation, the belt speed can be increased by changing sprockets. The speed, however, should not be reduced below 60 ft. per minute.

- Knockdown Arm

This arm is to push the bag onto the knock down plate. This is accomplished by holding the top one half of the bag stationary while the conveyor pulls the bottom of the bag. - Knockdown Plate

This plate is to receive bags from either the front or back side. - Turning Wheel

This wheel is located at the discharge end of the knockdown plate.