Vertical Continuous Conveyor

- Solutions By Product

- MHE Material Handling Equipment

- Vertical Lifting Solutions & Equipment

HA4.0 Offers two models in vertical continuous conveyors -

- CIRCULATING CONVEYOR

- CONTINUOUS VERTICAL CONVEYORS (CVC’S)

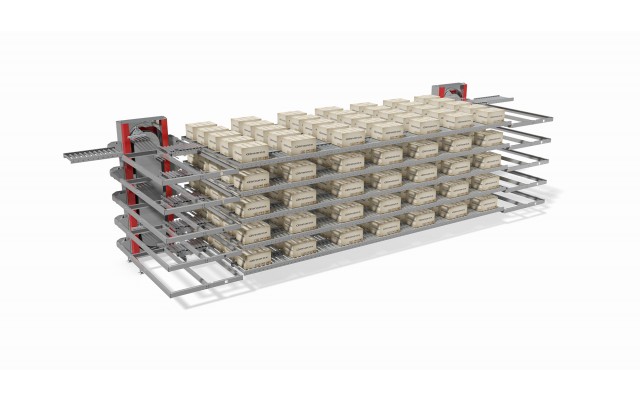

1) CIRCULATING CONVEYOR

HA4.0 vertical circulating conveyors using the paternoster principle are designed for applications where continuous random loading and unloading at multiple levels with high capacity is required, allowing separate loading and unloading on each floor.

Height up to 90 ft, loads up to 120 lbs., capacity up to 1,200 items per hour.

Height up to 90 ft, loads up to 120 lbs., capacity up to 1,200 items per hour.

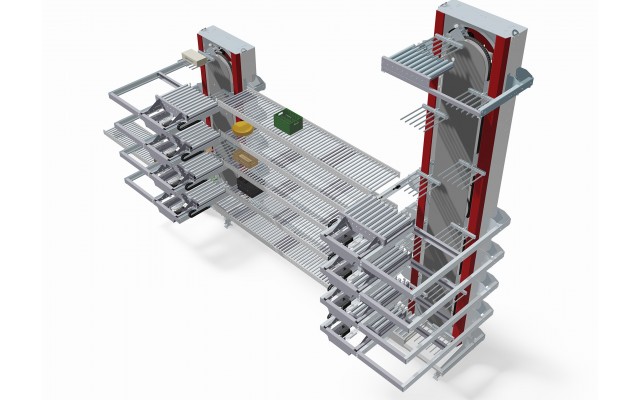

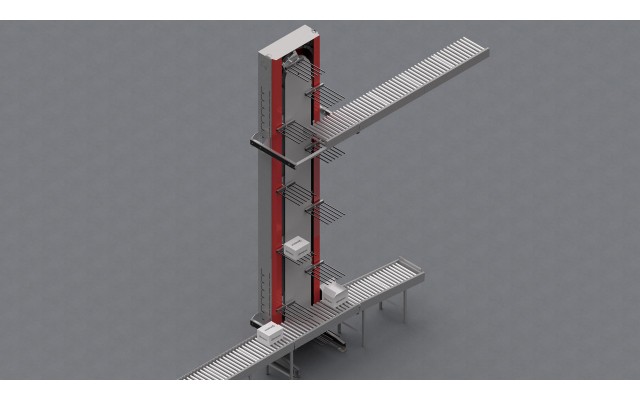

2) CONTINUOUS VERTICAL CONVEYORS (CVC'S)

HA4.0 Continuous Vertical Conveyors (CVCs) are used to elevate or lower containers, boxes, trays, packages, sacks, bags, luggage, pallets, barrels, kegs, and other articles with a solid surface between two levels, quickly and consistently at high capacity; on automatically loading platforms, in “S” or “C” configuration, on a minimum footprint.

Also known in the industry as S-Conveyors, box lifters or vertical lift units, HA4.0 Continuous Vertical Conveyors run in postal sorting facilities for trays and totes, airports and seaports for luggage handling, in industrial distribution warehouses, and in production facilities of all sorts.

Continuous vertical conveyors can be used for conveying upward and downward, and can be as high as 120 ft, while the small footprint compared to incline or spiral-type conveyors saves up to 90% of valuable floor space.