Stepper Feeder

- Solutions By Product

- AUTOMATION EQUIPMENT:

H+A STEPPER FEEDER:

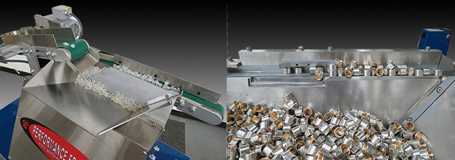

- H+A’s range of stepped feeders operates on the principle of a series of interrelating blades that lift the components from the integral bulk hopper.

- The movement is electrically, pneumatically or hydraulically powered, depending on the application.

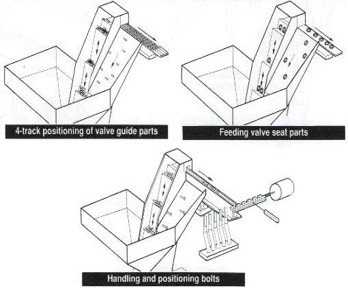

- The components being handled are discharged from the top blades onto a vibratory linear feeder or conveyor transfer track, where they are selected and orientated into the required position for presentation to machines or equipment for further operations.

- These feeders can handle a very wide range of items from small, delicate components (for assembly or machining operations), to handling billets for induction heating or press operations.

- Components can be orientated and fed in single or multiple lines to suit customers’ requirements. Ancillary escapement and transfer mechanisms can also be supplied as an integral part of these feeders.

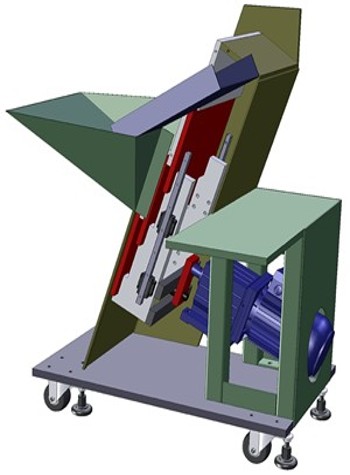

H+A BILLET STEPPER FEEDER:

We offer three types of billet feeders : Hydraulically billet feeders, motorised billet feeders or pneumatically operated. The type to be used depends on billet size.

Hydraulic billet feeders are ideal for billets ranging in size up to 100mm, round or square and up to 500mm long.

Motorised or pneumatically operated billet feeders are suitable for billets up to 30mm in diameter by 80mm long.

Billet feeders are usually used primarily for automatically feeding billets to heaters, but can be adapted for various other applications.

Bin tippers can be provided as an integral part of the feeder.

All necessary guarding and controls are provided. Standard discharge height can range from 1,000mm to 3,000mm to suit specific applications.

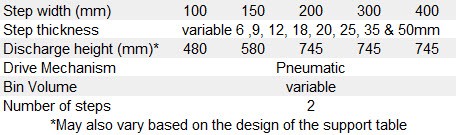

2 Step Feeder

4 Step Feeder

5 Step Feeder

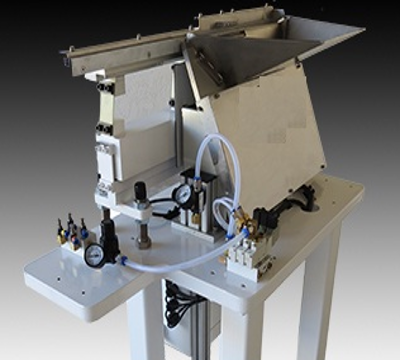

H+A -Single Step Feeder Model -

Low Cost Automates Feeding of Small Cylindrical and Spherical Parts

Features:

- Multiple drive options: The Economy Step Feeder is available with an electric motor or air-driven linear slide powering the step.

- Integrated hopper bin: Provides for storage of up to 1/4 cu. ft. of unoriented parts.

- Quiet operation: No Noise Pollution

- Extremely durable

- Gentle part handling: Because there is no vibration, part abrasion in a step feeder is significantly reduced. With the simple orientation technique of the step feeder system of lifting a single row parts out of the bin with the step, and final orientation performed on a vibratory inline, conveyor or air track, there is little to no wear on parts fed through a step feeder. This makes the Economy Step Feeder ideal for feeding fragile parts.

How it works ?

Bulk parts are lifted out of the integrated hopper bin by the step. The step thickness is selected so that a single row of parts is lifted. At the top of the step stroke, the parts drop onto a straight line track (vibratory inline, belt conveyor or air track), where additional orientation can be performed. Mis-oriented parts ejected from the orienting track can often drop directly back into the bin, or can be returned to the bin via gravity slide, air track or conveyor in situations where more complex orientation is performed on the orienting track.