Stack Car Parking Systems

- Solutions By Product

- MHE Material Handling Equipment

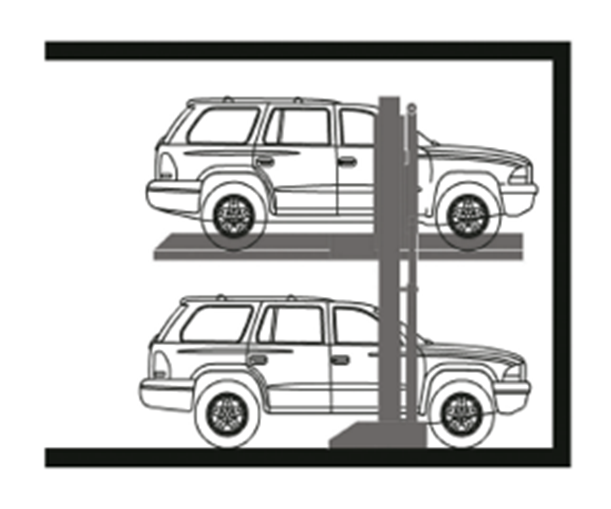

Stack parking systems offer an innovative solution to maximize parking capacity in limited spaces.

These systems come in two primary drive types:

1) Electro-Mechanical and

2) Hydraulic.

The dependent system requires the upper vehicle to be removed to access the lower vehicle, making it ideal for residential buildings, small offices, and locations with coordinated parking management. With features like simple button operation and robust safety mechanisms, these systems provide a practical solution to urban parking challenges.

Key System Advantages

Space Efficiency

Occupies smaller area while doubling capacity in equivalent space, perfect for urban environments with limited parking availability.

Simplified Design

Simple structure results in lower cost and easier maintenance, with flexible combination options for convenient installation and dismantling.

Safety Features

Comprehensive safety mechanisms include mechanical locking, non-return valve for cylinders, pressure release valve in powerpack, and optional vehicle presence sensors.

Additional Features

Front wheel stopper arrangement, IP55 protected motors and controls, powder coated structure with GI deck sheet, and optional EV charging facility.

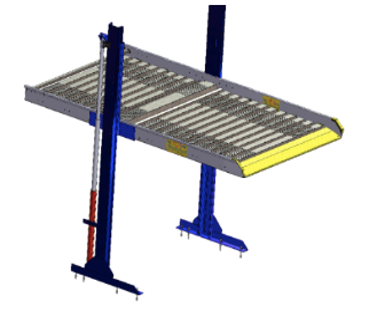

Hydraulic Stacker Components

Premium Materials

IS2062:E350 (A/BR/BO/C) Grade materials are used throughout the construction, ensuring structural integrity and longevity of the system under regular use conditions.

Balancing Chain

Diamond manufactures chain and sprocket used for pallet balancing. The chain contains case-hardened pins and heavier sidebars for increased fatigue strength and wear life in high-speed or abrasive applications.

Electrical Systems

All switchgear used in electrical control panel design adheres to IEC 61439 standard, ensuring reliable operation and safety compliance for the entire system.

Critical Mechanical Components

Roller & Shaft

Standard make Power Pack, Cylinder, Coupling and Hose Pipe

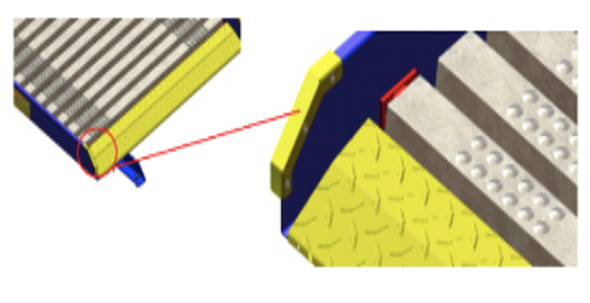

Front Wheel Stopper

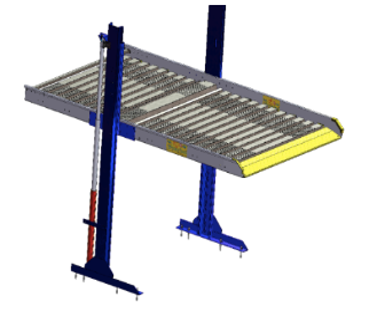

Platform and Safety Features

Pallet Sheet

Entry and Exit Ramp

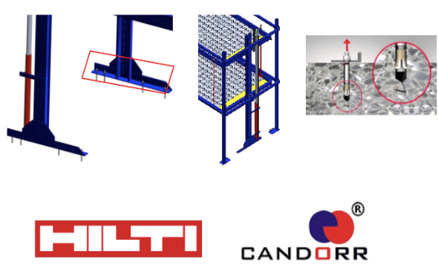

Base Plate

Seismic design anchor fasteners secure the base plate. Gusset plates serve dual purposes: joining components together and adding strength and support to each joint.

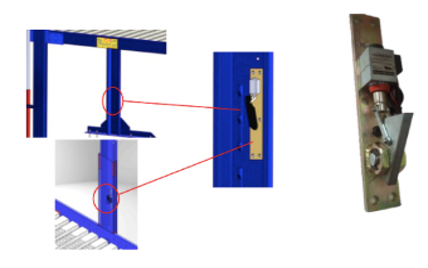

Safety Locks

Dual locking system prevents free falling of pallets during operation and when parked. Lock #1 works during up/down movement and parked position (G+1), while Lock #2 prevents free falling of car with pallet in parked position.

Limit Switch

Limit switch is provided in stacker which is of globally acclaimed companies like Schmersal, Teknic etc. Branded limit switch gives more life, easy for operate and very reliable.

Dimensional Specifications

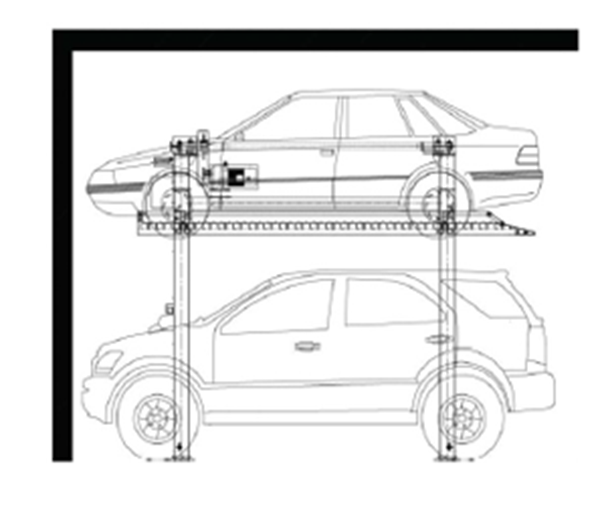

Electro-Mechanical Stack

- Easy to operate

- Low maintenance cost

- Ideal for residential and commercial complexes

- Independent Motorized system

Space Required

| Length | Width | Height |

|---|---|---|

| 5000-5200 | 2700-3000 | 3600-4400 |

Hydraulic Stack

- Easy to operate

- Low maintenance cost

- Ideal for residential and Larger commercial complexes

- Works on common power pack

- Cost effective

Space Required

| Length | Width | Height |

|---|---|---|

| 5000-5200 | 2700-3000 | 3600-4400 |

Technical Specifications

| Speed | 2 Meters / Minute (each stack) |

|---|---|

| Operation | Key with Push button operation |

| Power Supply | 415 V, 3 phase, 50 Hz |

System Performance

Three Level Simple Stacker (G+2)

Dependent System

According to the drive mode of lifting, it can be categorized into two types:

- Electro-Mechanical & Hydraulic type.

Key Features Of The System:

- Occupying smaller area, the capacity doubles in equivalent area.

- Simple structure, lower cost.

- Flexible combination, convenient installation & dismantling.

- Button operated, simple and convenient.

- Compact Geared box Motor mounted on the pole of stacker for Mechanical Stacker

- Power pack with Telescopic Cylinder to operate Hydraulic Stacker.

- Safety Features: Mechanical Locking, non return valve for

cylinder and pressure release valve in powerpack vehicle presence sensor (optional). - Front Wheel stopper arrangement on platform for proper positioning of car.

- Motors and Controls are with IP55 Protection.

- Powder coated structure with GI Deck sheet.

- EV Charging facility can be provided on demand.

- Limit switch for Upper Car Movement.

- Very low maintenance and easy for servicing.

2 Stage Dependant Stack

- Easy to operation & Maintenance

- Manual System

- Space Effective

Space Required

| Pit Length | Pit Width | Pit Height | Above Height |

|---|---|---|---|

| 6000 | 2500-7200 | 2200-2600 | 2200-2400 |

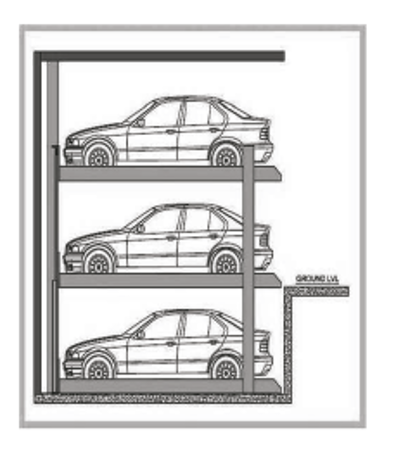

Three Level Simple Stacker With One Pit Level (G-1 +1)

Dependent System

According to the drive mode of lifting, it can be categorized into two types:

- Electro-Mechanical

- Hydraulic type.

Key Features Of The System:

- Occupying smaller area, the capacity doubles in equivalent area.

- Simple structure, lower cost.

- Flexible combination, convenient installation & dismantling.

- Button operated, simple and convenient.

- Compact Geared box Motor mounted on the pole of stacker for Mechanical Stacker

- Power pack with Telescopic Cylinder to operate Hydraulic Stacker.

- Safety Features: Mechanical Locking, non return valve for

cylinder and pressure release valve in powerpack vehicle presence sensor (optional). - Front Wheel stopper arrangement on platform for proper positioning of car.

- Motors and Controls are with IP55 Protection.

- Powder coated structure with GI Deck sheet.

- EV Charging facility can be provided on demand.

- Limit switch for Upper Car Movement.

- Very low maintenance and easy for servicing.

3 Stage Dependant Stack

- Easy to operation & Maintenance

- Manual System

- Space Effective

Space Required (Pit Type)

| Pit Length | Pit Width | Pit Height | Above Height |

|---|---|---|---|

| 6000 | 2100-7300 | 2200-2600 | 4000-4600 |

Space Required (O G Type)

| Length | Width | Height |

|---|---|---|

| 5500-6000 | 2800-3000 | 5800-6500 |