Accessories of Vibratory Feeders

- Solutions By Product

- AUTOMATION EQUIPMENT

- Vibratory Feeding System

- HA provides various accessories for Vibratory Feeders.

- The advantage of buying accessories from HA is that you get a complete system ready for usage.

- It becomes a plug and play solution. Plus you need not have to worry about matching / integrating the Vibratory Feeder with chutes and other parts.

- HA can provide various accessories like controllers, bowl coating etc to make your bowl feeder purchase a complete solution.

1) Vibratory Drives – HA offers 6 Models –100 Dia, 200 Dia, 300 Dia, 400 Dia, 500 Dia

HA Vibrator drive units are correctly engineered to give stable performance at high speed with minimum maintenance. They come with CE Marking, thus conforming to the stringent European Safety Norms for Machinery Safety, Low Voltage Directive as well as the Electro Magnetic Compatibility.

Highlights

HA uses totally encapsulated type coils with adequate power for respective models. A removable guard / cover is provided for safety for all vibrator drives. All drive units are for FULL WAVE Operation (100 Cycles) and hence the energy consumption of HA vibratory drive units is 40% less than its competitors who offer HALF WAVE Operation. For heavy components and bigger bowls, HA can also provide HALF WAVE Vibrators .

HA uses totally encapsulated type coils with adequate power for respective models. A removable guard / cover is provided for safety for all vibrator drives. All drive units are for FULL WAVE Operation (100 Cycles) and hence the energy consumption of HA vibratory drive units is 40% less than its competitors who offer HALF WAVE Operation. For heavy components and bigger bowls, HA can also provide HALF WAVE Vibrators .

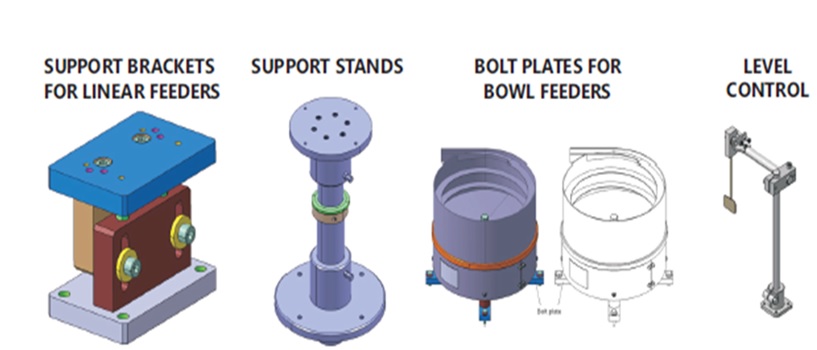

2) Stands

HA can provide Stands for mounting the Vibratory Feeders. The advantage of standard HA stands are its height adjustment. Standard units have (+/-) 100 mm ht. adjustment while even (+/-) 200 mm height adjustment can also be provided in case of requirement. HA stands also come with leveling screws with optional provision for grommeting to the ground.

Stands can be of the following types:

- Cubical : This can be either a 400 x 400 mm or 500 x 500 mm square stand with height adjustment and space for storage below.

- Single Post: This is a single tubular Stand with provision for height adjustment. Its advantage is its compactness.

- Table Type: In case any other mechanism / system needs to be mounted on the stand, table type stand can be used.

3) Chutes

Once the component comes out of the bowl feeder, it needs to be taken to the next station, for this either a gravity chute or a linear track has to be used.

- Gravity Chutes : Components can move with gravity if the correct inclination is provided. HA can help you decide on the correct inclination for your component.

- Linear Chute :In case you require the chute to be horizontal for feeding to the next operation, then a linear chute is required. A linear chute is mounted on a linear vibrator and can be anywhere from 300 mm to 1500 mm in length or even more.

- Silos :HA offers Silo type Hoppers for providing higher capacities. Usually, the number of components which can be loaded in a Vibratory Bowl Feeder is constrained by the Weight and the Volume of the components. In order to increase the loading capacity, usually Auxiliary Hoppers are provided. The disadvantage of Auxiliary Hoppers is the extra space which they occupy and plus the extra cost and electrical consumption and wiring required for the same. As against this, Silos offer the advantage of increased loading capacity and they do not require any Electrical Supply. The increase in height is also nominal. The overall Table size also does not increase to that extent. Though the Silo has a lot of advantages, the only disadvantage is that it can only be used for certain components like Needles, Rollers etc. However, it cannot be used for components like screws, hooks etc.

Chute

Gravity Chutes

Bulk Hoppers

- HA offers bulk hoppers for providing higher capacities. Usually, the number of components which can be loaded in a Vibratory Bowl Feeder is constrained by the Weight and the Volume of the components.

- In order to increase the loading capacity, usually Auxiliary Hoppers are provided.

- The disadvantage of Auxiliary Hoppers is the extra space which they occupy and plus the extra cost and electrical consumption and wiring required for the same.

- As against this, Silos offer the advantage of increased loading capacity and they do not require any Electrical Supply. The increase in height is also nominal.

- The overall Table size also does not increase to that extent. Though the Silo has a lot of advantages, it cannot be used for all types of components and this is where the Bulk Hoppers come into play.

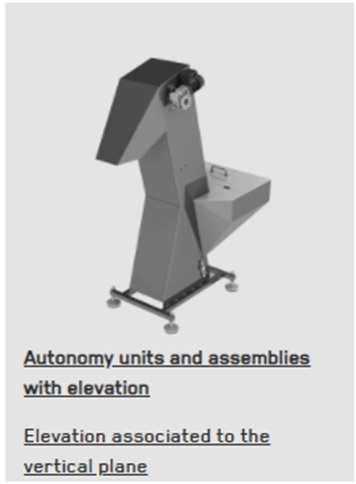

Bulk Elevators

- HA can offer bulk elevators for providing higher capacities. Usually, the number of components which can be loaded in a vibratory bowl feeder is constrained by the weight and the volume of the components.

- In order to increase the loading capacity, usually auxiliary bulk elevators are provided.

- The disadvantage of auxiliary bulk elevators is the extra space which they occupy and plus the extra cost and electrical consumption and wiring required for the same.

- The advantage is the ground level loading which is possible with bulk elevators.

- The loading height in case of bulk hoppers increases but in case of bulk elevators, reduces substantially.

Pneumatic Escapements

- HA offers a unique pneumatic escapement. It is designed in such a way that on receipt of a signal from a relay / sensor or PLC, the escapement is actuated and a single component is released.

- While releasing one component, the one behind that component is held in place.

- The best part of the HA pneumatic escapement is that it works on just one pneumatic cylinder as against two pneumatic cylinders which most manufacturers offer.

- Results not only in saving the running cost but also the initial cost. The HA pneumatic escapement is optionally provided with HA vibratory bowl feeders.

- However, HA can also sell only the pneumatic escapements which customers can integrate at their end.

- The full HA pneumatic escapement comes with a FESTO make cylinder (other makes are also available), a F/R/L unit and solenoid valve.

- Additionally, HA provides all the electrical inputs like transformer and other circuitry so that using it becomes very hassle free and easy for the customer.

- HA has got two models of the pneumatic escapement and depending upon the component dimensions, the correct type of escapement can be recommended by the trained application engineers at HA.

- Due to the very high popularity of this concept, the HA pneumatic escapement is kept in stock and can be provided within a short period and at a very competitive price.

Non-Vibrating Parts

- In case any component needs to be picked up by a pick and place, it is most convenient to use a non-vibrating part with a stopper for pick up of the same.

- HA can provide a non-vibrating part with a stopper at the end of the chute (either gravity or linear track) from where the pick and place can conveniently pick up the component.

- Application engineers at HA can always discuss your requirements and suggest the correct pick up position for your components.

X-Y Tables

- HA offers X-Y Tables for Vibratory Bowl Feeders. These are available in two Models –Model 250.Model 400 ,X-Y tables make fine adjustments on X axis and Y axis possible.

- This along with the Z adjustment which is available on HA stands give a tremendous benefit to machine builders / system integrators who can thereby reduce the time taken for integration.

- This accessory also finds usage when various sizes of components are being fed to a centreless grinding machine.

- This helps in fine adjustment to accommodate the various sizes of components plus helps while dressing the grinding machine wheel.

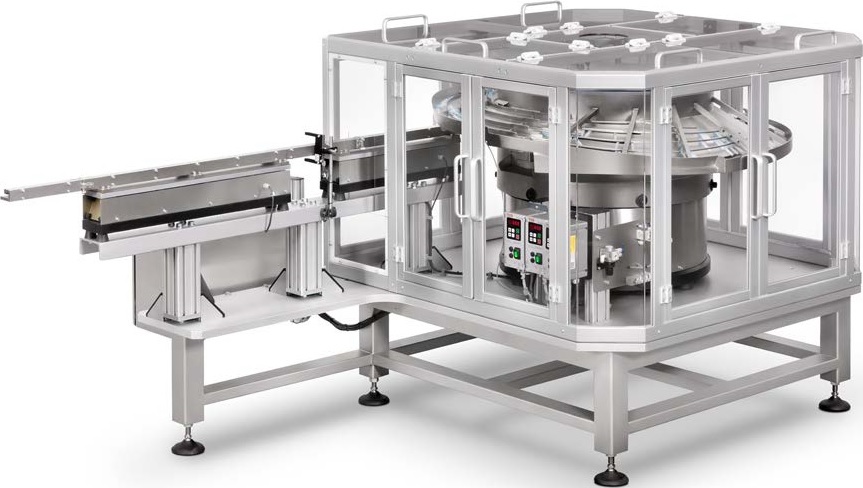

Noise Enclosures / Noise Suppressors

- HA offers three types of noise enclosures for vibratory bowl feeders, namely, Square or rectangular mild steel cover lined with acoustic foam on the inside, round shaped mild steel cover with acoustic foam lined on the inside and thirdly, acrylic enclosure fixed with aluminium extruded Sections.

- Depending upon the budget, type of component, model of the bowl feeder and the noise reduction requirement of the customer, application engineers from HA can recommend the correct type of noise enclosure for your vibratory bowl feeder.

- In case a new vibratory bowl feeder is ordered on HA, noise enclosures are optionally provided to the customers. However, HA can also provide noise enclosures for old vibratory bowl feeders of any make.

- A noise reduction of between 10 Db to 20 Db can be achieved with the help of HA noise enclosures. In case of special applications like pharmaceutical requirements, even stainless steel noise enclosures can also be provided with special washable acoustic foam.

- The HA mild steel or stainless steel noise enclosures come with toggle clamps for easy removal and fastening. Additionally, the top cover is made of transparent acrylic with a particular thickness and hinges which not only reduces the noise but helps the operator to check whether the number of pieces in the bowl have reduced or require replenishment.

- HA can also provide a level controller with the noise enclosure and give a ring / flash a bulb in case the levels of components in the bowl reduce. This feature is very popular with most customers as it relieves the operator from continuously checking the level of components in the bowl.

- HA maintains a stock of various sizes of noise enclosures and thus faster deliveries are possible.